The Growing Role of Artificial Intelligence in Machining and Manufacturing

In the ever-evolving landscape of manufacturing, Artificial Intelligence (AI) is emerging as a transformative force, reshaping traditional processes and enhancing efficiency across various industries. One notable area where AI is making significant strides is in machining and manufacturing. From automating mundane tasks to optimizing complex processes, AI is revolutionizing the way products are designed, produced, and delivered. This article explores the growing role of AI in machining and manufacturing and its implications for the future.

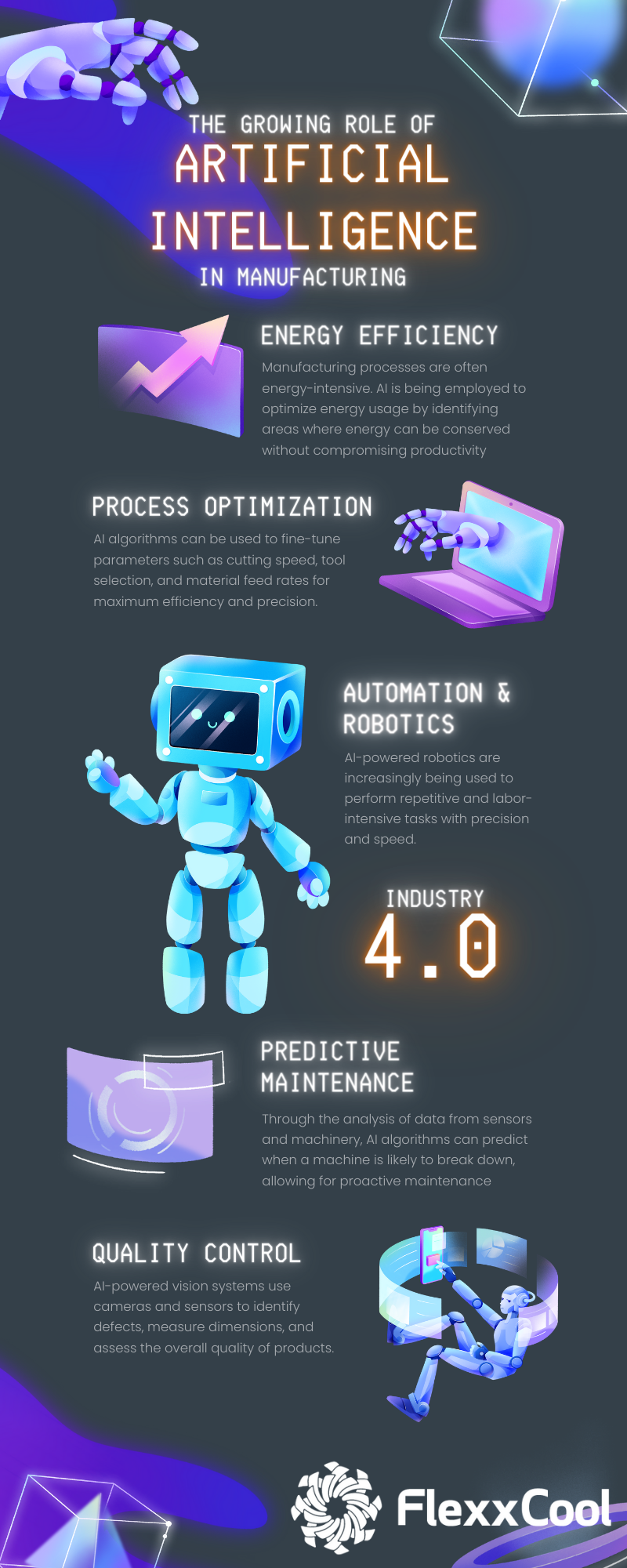

Energy Efficiency:

Manufacturing processes are often energy-intensive. AI is being employed to optimize energy usage by identifying areas where energy can be conserved without compromising productivity. From controlling machinery to managing lighting and HVAC systems, AI contributes to creating more sustainable and environmentally friendly manufacturing practices.

Process Optimization:

AI algorithms are adept at analyzing vast amounts of data to identify patterns and optimize manufacturing processes. In machining, AI can be used to fine-tune parameters such as cutting speed, tool selection, and material feed rates for maximum efficiency and precision. This optimization leads to improved productivity, reduced waste, and enhanced overall performance.

Automation and Robotics:

One of the primary applications of AI in machining and manufacturing is automation. AI-powered robotics are increasingly being used to perform repetitive and labor-intensive tasks with precision and speed. These robotic systems are equipped with sensors and cameras that allow them to adapt to changes in their environment, making them versatile and efficient in handling various manufacturing processes.

Predictive Maintenance:

AI is playing a crucial role in predictive maintenance, helping manufacturers anticipate equipment failures before they occur. Through the analysis of data from sensors and machinery, AI algorithms can predict when a machine is likely to break down, allowing for proactive maintenance. This not only reduces downtime but also extends the lifespan of equipment, ultimately leading to cost savings for manufacturers.

Quality Control and Inspection:

Ensuring product quality is paramount in manufacturing. AI-powered vision systems are being employed for real-time quality control and inspection. These systems use cameras and sensors to identify defects, measure dimensions, and assess the overall quality of products. This not only enhances the accuracy of inspections but also speeds up the production process by identifying and rectifying defects early on.

Supply Chain Management:

AI is transforming supply chain management by providing real-time visibility and control over the entire manufacturing process. From demand forecasting to inventory management, AI algorithms analyze historical data and market trends to make accurate predictions. This enables manufacturers to optimize inventory levels, reduce lead times, and respond swiftly to changes in customer demand.

Customization and Personalization:

As consumer preferences continue to diversify, manufacturers are under pressure to deliver customized and personalized products. AI facilitates this by enabling the mass customization of products through adaptive manufacturing processes. This not only enhances customer satisfaction but also allows manufacturers to respond quickly to changes in market trends.

FlexxCool:

The FlexxCool automated coolant management system supports AI-driven optimization of machining processes, reducing downtime, and boosting productivity. Seamlessly integrated with CNC machines, our system maintains optimal coolant levels and concentrations, extending tool life and enhancing machining accuracy. Explore how our solution is integral to lights-out robotics in revolutionizing your manufacturing operations!

The integration of AI in machining and manufacturing is transforming the industry by enhancing efficiency, reducing costs, and improving overall quality. As technology continues to advance, we can expect even greater innovations in the field, paving the way for a new era of smart, adaptive, and sustainable manufacturing. Embracing the capabilities of AI is not just a technological leap but a strategic imperative for manufacturers looking to stay competitive in the rapidly evolving landscape of modern industry.