Coolant Evaporation

Ambient temperatures and varying work processes can lead to an increased coolant evaporation rate in a shop. There are three factors that relate to evaporation:

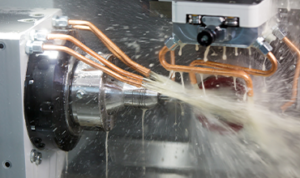

Machining Processes:

The type of machining your shop can increase coolant evaporation. An example is deep hole drilling.

Deep hole drilling is when a deep hole needs to be drilled into the machined material. You need to optimize coolant during the drilling process by shooting it at a faster rate into the hole that is being drilled in order to keep debris from getting stuck and keep things cool during the process.

Ultimately, this process causes a lot of mist or evaporation of the water in the coolant mixture.

Climate:

The climate you are located in can also play into the amount of evaporation you see. For example, suppose you are located in a dryer climate where precipitation is low. In that case, the chances of water evaporation in your coolant mixture are higher than somewhere that has more humidity or a high precipitation rate.

Shop Environment:

Work environments vary from shop to shop. For example, suppose you are in a climate-controlled environment. In that case, the chances of increased evaporation are a lot lower than in a shop that opens its doors for airflow, increasing fluctuating conditions in the shop and exposure to weather.

The FlexxCool system can accommodate your shop’s needs regardless of machining processes, climate, or shop environment. With our UTC Process, a specific top-up is delivered to each machine, maintaining consistent concentration targets and coolant levels by supplying exact top-up amounts when needed.

To read more about the FlexxCool system click here or contact us.